PTWA Overview

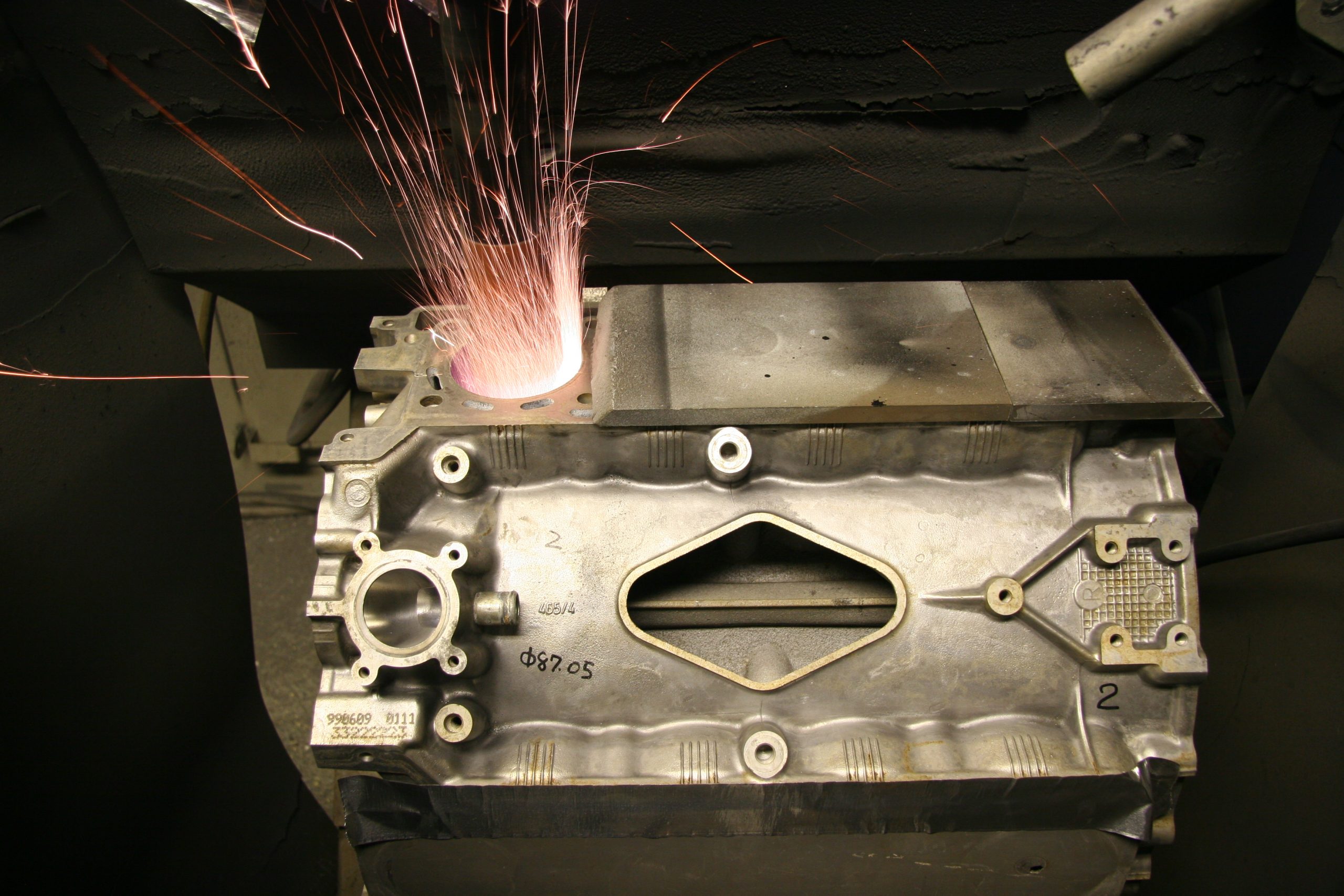

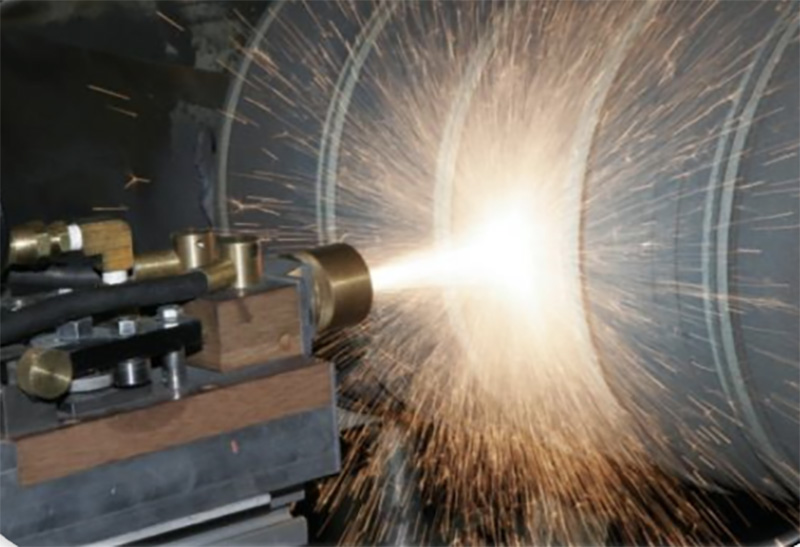

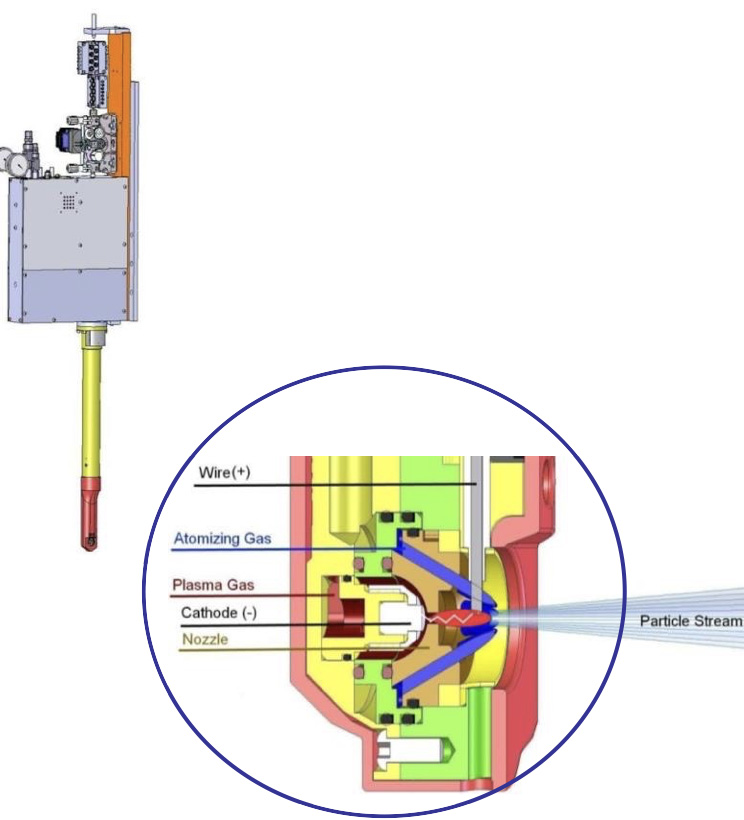

Plasma Transferred Wire Arc is a unique manufacturing process that can deposit a coating on the internal surface of a cylinder, or on the external surface of a part of any geometry. Any conductive wire can be used as the feedstock material, including “cored” wire. Refractory metals as well as low melt materials are easily deposited.

Thermal Spray Overview

Thermal spray is a process of depositing molten, semi-molten, or solid particles onto a substrate to form a functional coating or a freestanding part. The particles travel at high velocity, causing them to flatten on impact with the substrate. These flattened particles, known as “splats,” build up to form the final coating or part. Thermal spray coatings are used in a number of industries because they offer benefits including corrosion resistance, increased conductivity, wear reduction, repair of damaged surfaces, thermal insulation, electrical insulation and biological functions such as bio-activity.

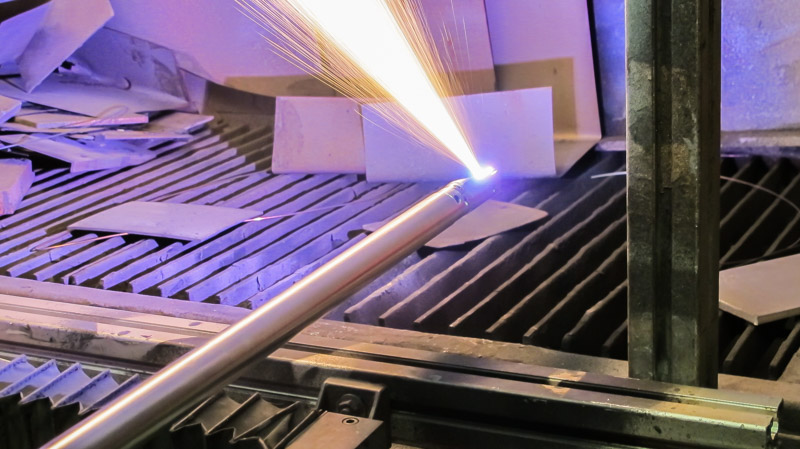

Two Wire Arc Electrospray

Flame-Spray has been providing two wire arc systems since 1964. The Two Wire Arc Eectrospray system has been engineered to provide a robust, reliable and economical operation while producing high quality coating at high deposition rates. The sturdy front drive system features long life components designed for continuous OEM applications. Hand held models are also available. Electrospray can be used with a solid or cored feedstock wire with diameters of 14 ga., 11 ga.

or 1/8 in. wire. The Electrospray controls allow the user to control air pressure, spray voltage, and wire feed rate with easy local or remote, PLC or pendant controls. The power source is an advanced solid state design and is available in 350, 450 and 600 amp models. All power sources are rated at 100% duty cycle and allows continuous voltage from 14-44 volts. Both United States and European electrical inputs are available.

Electrospray coating applications include OEM, repair work, wear resistance and anti-corrosion coatings. Materials such as zinc, aluminum, copper, bronze, steel-based alloys and nickelbased alloys in both solid and cored wire form are examples of materials that can be sprayed using the Electrospray process.

PTWA

Our Projects

2018 Ford GT350

READ MORE

2011 Ford GT500

READ MORE

2018 Ford F-150

READ MORE

2018 Ford Mustang GT

READ MORE